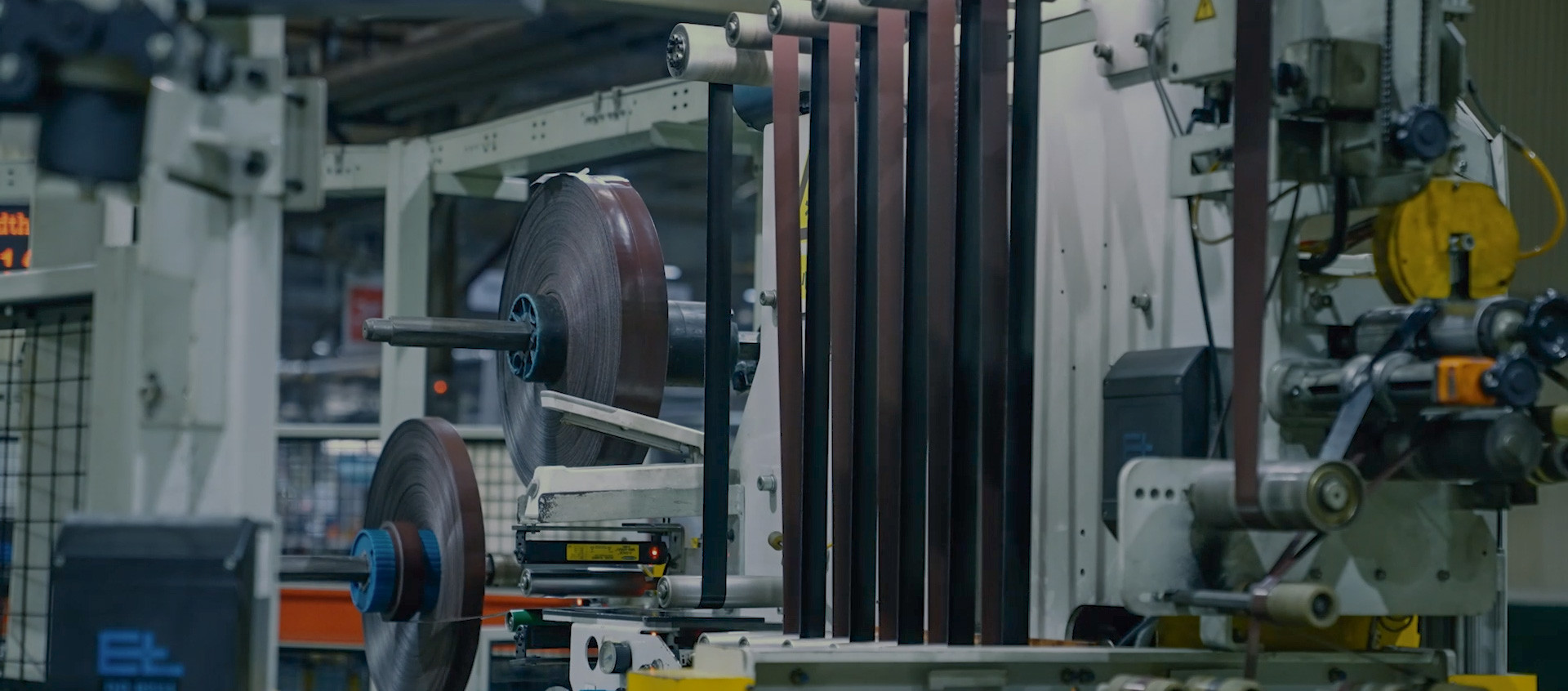

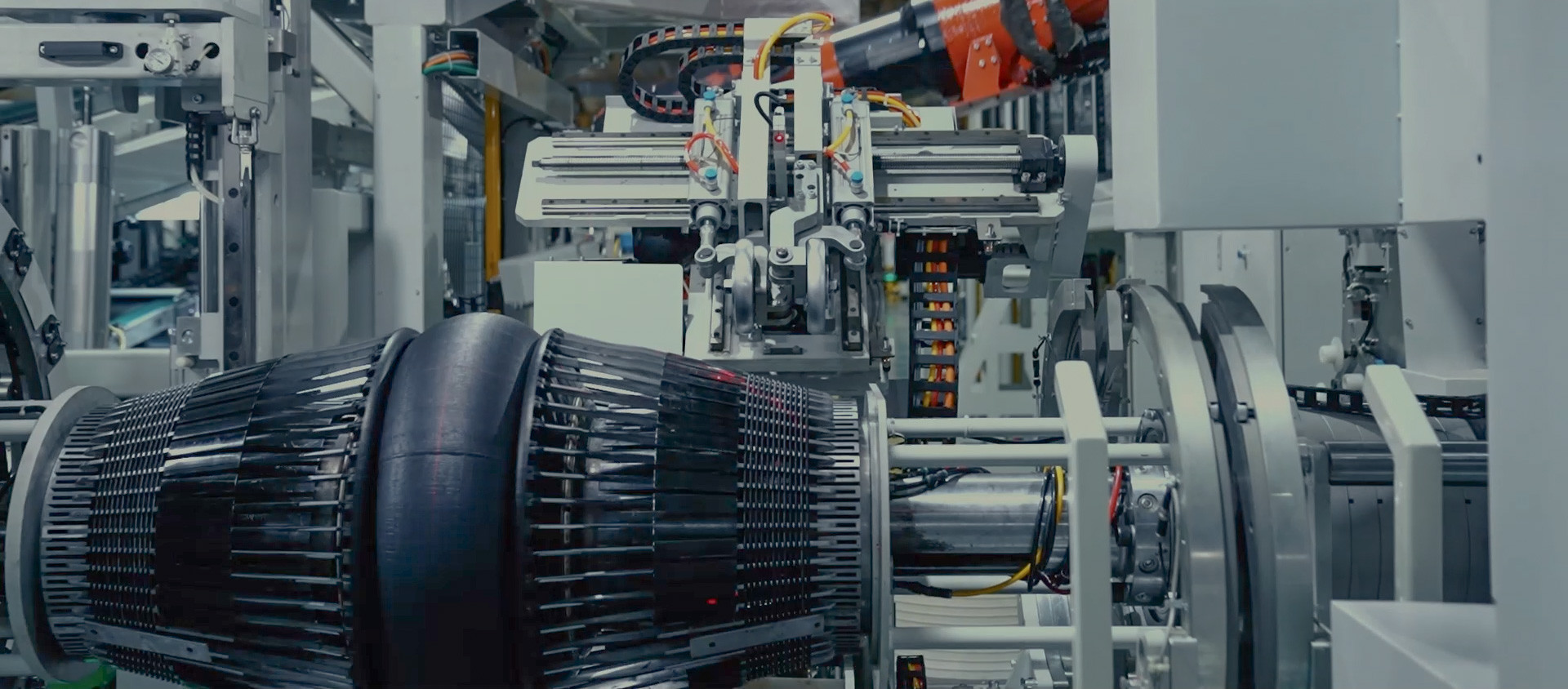

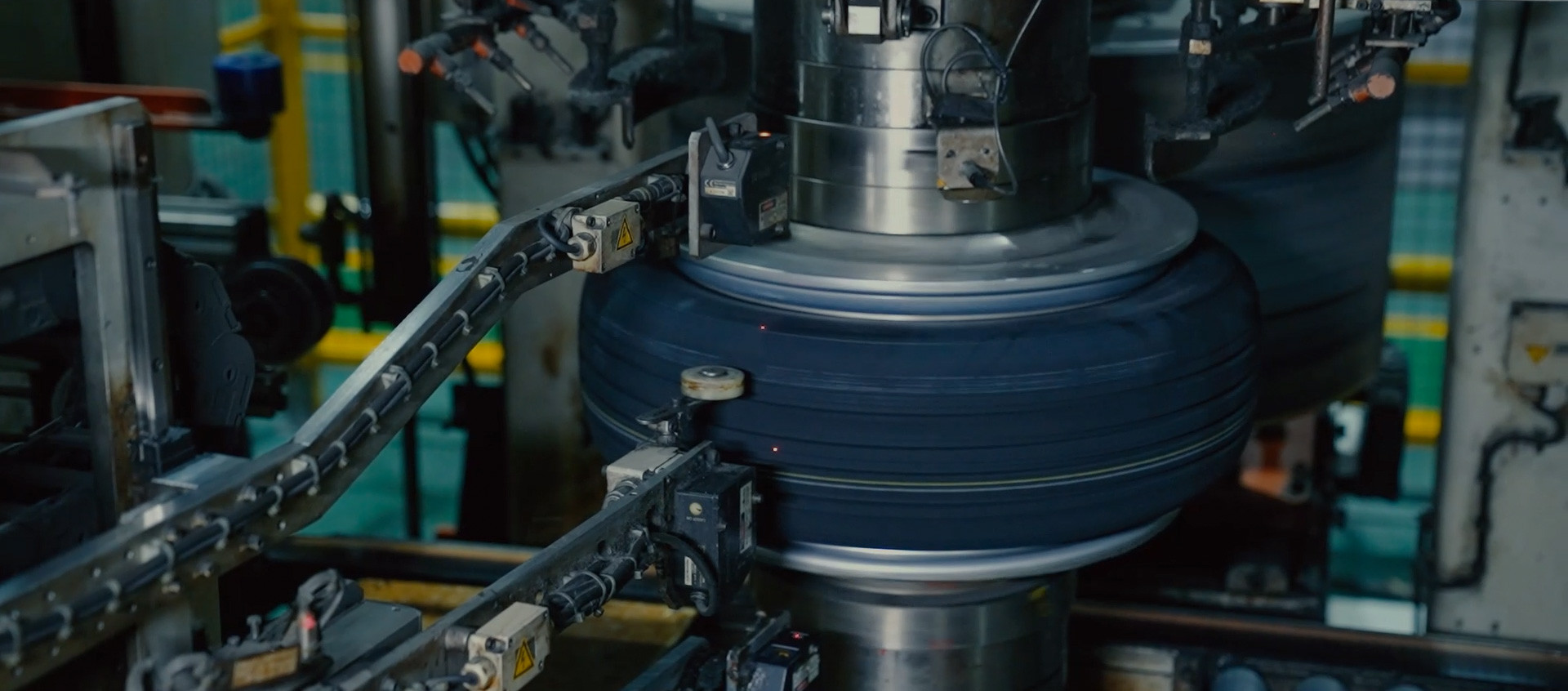

Our Mission is “Make Great Tires”

"Make Great Tires" is Sailun’s solemn commitment to consumers, users, and society. It’s the ultimate embodiment of the highest principles and values that all Sailun people adhere to. Sailun focuses on the development and application of rubber tire technology and services, continuously striving for innovation, conducting research, and maintaining an unwavering commitment to quality. Thus, Sailun provides users and society with superior quality, more environmentally friendly tire products and services, making human mobility safer and freer, while enhancing the efficiency and harmony of societal operations.