Company-Wide Participation and Continuous Improvement Enable us to Deliver Greater Value to our Customers

Our quality policy is centered on company-wide participation, continuous improvement, and an ongoing commitment to delivering greater value to our customers. Focusing on enhancing product competitiveness, responding to the needs of end users, optimizing products-associated services, and leading in production scale, we have established a fully implementable, end-to-end quality management system spanning the entire process flow from customer input to customer satisfaction, covering all production stages, and integrating the complete value chain. Through systematic quality planning, control, and improvement, we foster a company-wide quality culture, improve operational quality and efficiency, ensure the delivery of products and services that meet customers’ requirements, and strive for outstanding quanlity.

-

-

Product Planning/Requirements Quality Management

1Establish a systematic, IT-driven requirements management platform to strengthen requirements management and monitor its operation.

2Develop standardized supporting system requirements and deploy them across our overseas factories to ensure smooth passage of OEM entry audits and achieve sustainable market presence.

3Conduct systematic research on frontier regulations to enable rapid identification, interpretation, and response to meet market compliance needs.

4Establish a comprehensive preventive delivery quality control mechanism, implement closed-loop complaint management, oversee rapid problem resolution, and enhance customer satisfaction.

-

-

R&D Quality Control

1Conduct finite element analysis and competitive product benchmarking during product development to ensure product performance meets design targets.

2Refine the quality gate evaluation mechanism, establish product-line-specific control criteria, and transit from compliance-based to effectiveness-focused quality gate management.

3Develop product-line-specific technology maps to provide data support for quality gate reviews.

-

-

Raw Material Supplier Quality Control

1Establish a preventive trend analysis mechanism for suppliers and conduct horizontal comparative performance benchmarking to progressively enhance the stability of raw material quality. Implement a supplier qualification management system to improve the effectiveness of potential supplier audits, identify supplier risks in advance, and ensure newly approved suppliers meet our requirements.

2Develop a supplier performance evaluation mechanism and implement tiered controls—including improvement plans, supply suspension, and elimination—based on performance, thereby achieving collaborative quality enhancement with suppliers.

-

-

Manufacturing Quality Control

1Foster a quality culture ingrained in the principle— ""Do it Right the First Time"", implement consistent product quality requirements across our manufacturing facilities, support global intelligent manufacturing operations, and create value for our customers.

2Develop differentiated product release standards and progressively position premium products as industry benchmarks.

3Leverage AI vision technology to gradually reduce and ultimately eliminate human involvement in quality checks, thereby advancing intelligent inspection of finished products.

4Systematically enhance process capabilities and establish a big data platform to achieve rapid risk identification, timely decision-making, consistent control over the manufacturing process, and uniform product output.

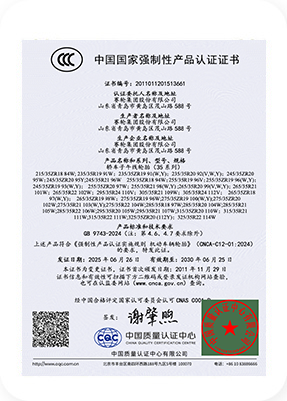

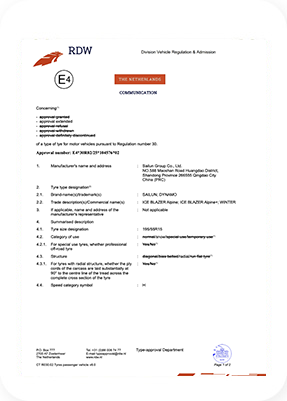

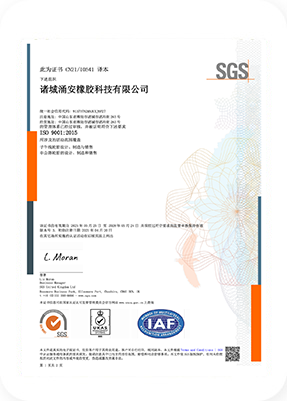

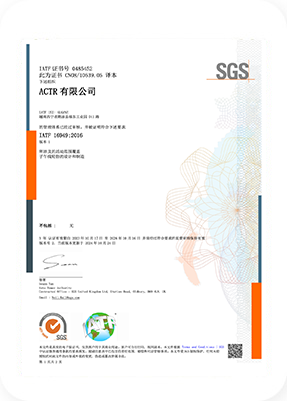

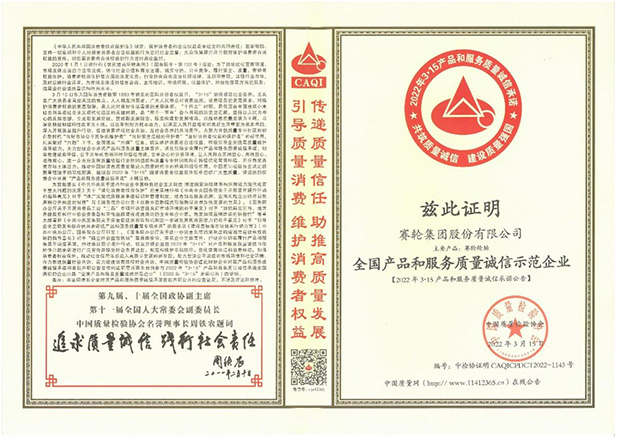

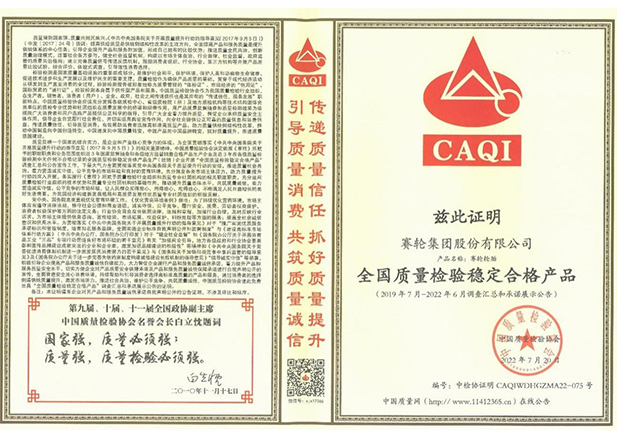

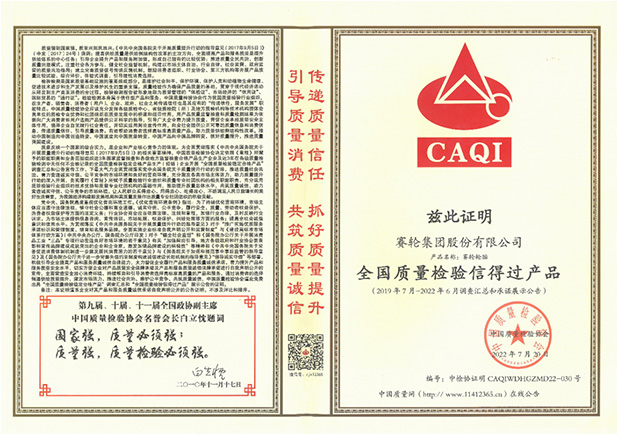

Global Quality Certifications and Accreditations

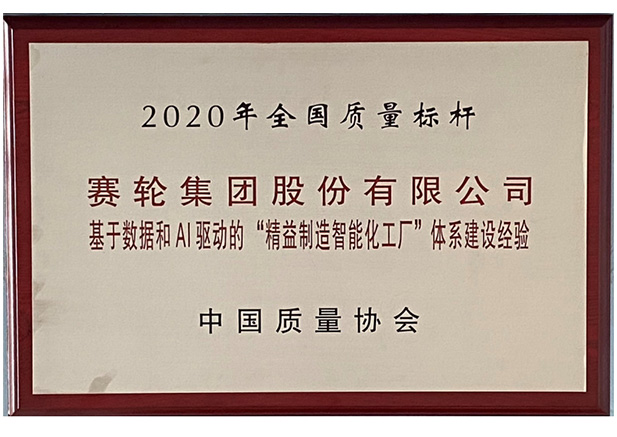

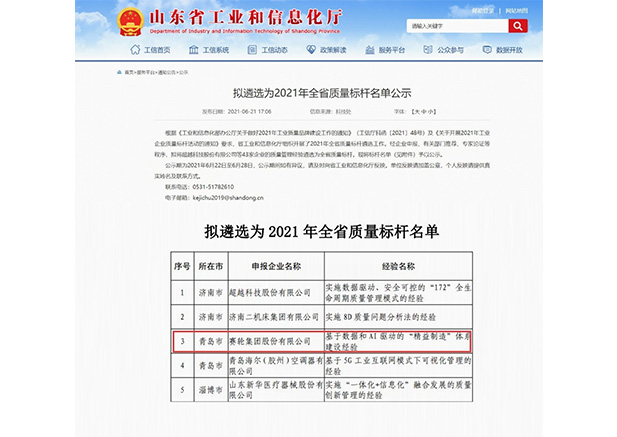

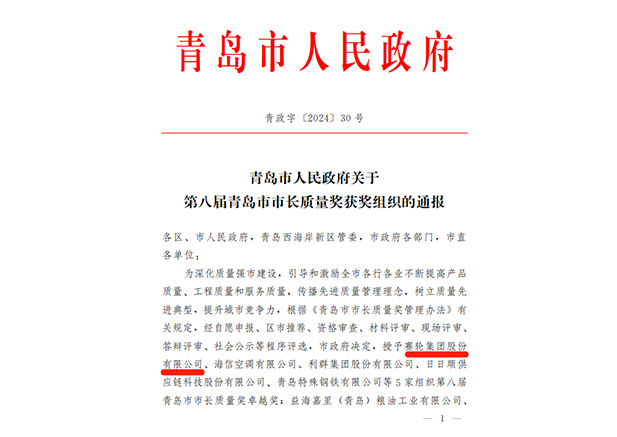

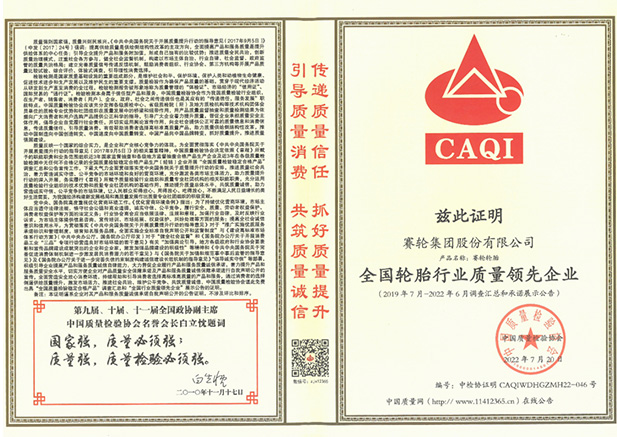

We have obtained a variety of certifications and accreditations from nearly 58 countries worldwide, including ISO 9001:2015, IATF 16949:2016, ISO 10012:2003 Measurement Management System Certification (AAA), CCC Certification, and CNAS Laboratory Accreditation. These certifications and accreditations ensure our products deliver optimal performance and guarantee safety while fully meeting the standards of different countries. We have been honored with multiple awards and accolades, including the National Consumer Quality Information Guarantee Product, National Product and Service Quality Integrity Demonstration Enterprise, National Stable and Qualified Product in Quality Inspection, National Trusted Product in Quality Inspection, National Leading Quality Enterprise in Tire Industry, the 8th Qingdao Mayor Quality Award, 2021 Shandong Provincial Quality Benchmark, and 2020 National Quality Benchmark.